Check valves in the plumbing world play a crucial role in ensuring the proper flow of liquids within a system. These small yet powerful devices allow fluid to move in only one direction, preventing backflow that could damage equipment, contaminate water supplies, or cause costly repairs. Understanding how check valves work and their importance in plumbing systems is essential for professionals and homeowners alike.

How Check Valves Work?

At its core, a check valve is a mechanical device that automatically permits the flow of water, gas, or other fluids in one direction, blocking any attempt of reversal. They do not normally require manual operation; instead, they rely on the pressure difference between the inlet and outlet. When the pressure on the inlet side exceeds that on the outlet side, the valve opens, allowing liquid to flow. When the pressure reverses, the valve closes to prevent backflow.

This automatic mechanism is vital in plumbing systems where backflow can lead to contamination, especially in drinking water systems, or where reverse flow could damage pumps or other sensitive equipment.

Types of Check Valves

There are several types of check valves used in plumbing, each with specific applications depending on the system’s requirements:

Swing Check Valves: This type features a hinged disc inside the valve that swings open when fluid moves in the correct direction and closes when the flow reverses. These types of valves are often used in horizontal pipes and are ideal for water systems where the flow is constant.

Ball Check Valves: These use a ball that sits on a seat within the valve. When fluid flows in the proper direction, the ball is pushed off the seat, allowing passage. If the flow reverses, the ball returns to the seat, blocking the flow. Ball check valves are common in sump pump systems and sewage ejector systems.

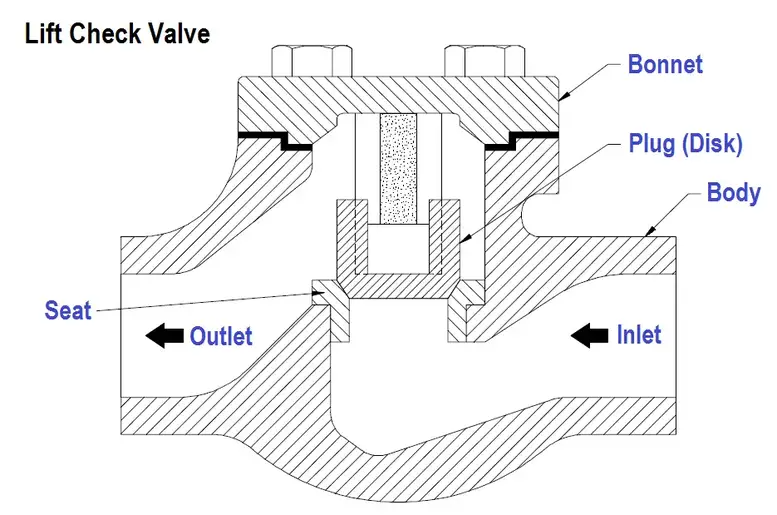

Lift Check Valves: These feature a guided disc that lifts off the seat when fluid pressure is sufficient and drops back into place when the flow stops or reverses. Lift check valves are often used in high-pressure systems and can be installed in both horizontal and vertical piping.

Diaphragm Check Valves: These valves have a flexible diaphragm that opens and closes in response to pressure changes. They are frequently used in wastewater applications where contamination and sediment are concerns.

Applications of Check Valves in Plumbing

Check valves are used in various parts of plumbing systems to ensure safe and efficient operation. One of the most common applications is in domestic water systems, where they prevent the reverse flow of water into the main supply. This is particularly important in preventing contamination of potable water with potentially harmful substances from other sources, such as chemicals from heating systems or graywater from washing machines.

In addition to potable water systems, check valves are essential in sump pump and sewage systems. In these cases, the valve prevents wastewater from flowing back into a home’s plumbing, protecting the property from flooding or sewage backups.

Check valves are also critical in pump systems. For example, in well water systems, a check valve is placed after the pump to prevent water from flowing back into the well when the pump is turned off. This maintains pressure in the system and reduces the workload on the pump, extending its lifespan.

Importance of Backflow Prevention

Backflow prevention is a critical function of check valves in plumbing systems. Without them, contaminated water could mix with clean water, leading to potential health hazards. In municipalities, backflow can occur when there is a sudden drop in water pressure, such as during a firefighting event or a water main break. In such situations, water from homes, gardens, or industrial sites could flow back into the public water supply, carrying chemicals, bacteria, or other harmful substances with it.

Installing check valves in strategic locations within the plumbing system is an effective way to prevent these issues. For example, they are often required by building codes in irrigation systems, hot water heating systems, and any plumbing that connects to potentially contaminated sources.

Maintenance and Lifespan

Like any plumbing component, check valves require regular maintenance to ensure they function properly. Over time, debris or sediment can build up on the valve, preventing it from closing completely. This can cause leaks or a loss of pressure in the system, so regular inspections and cleanings are necessary to prolong their lifespan.

In industrial or high-use environments, they may need to be replaced periodically due to wear and tear. However, with proper maintenance, they can last for many years. It is also essential to ensure that the correct type of check valve is used for the application to prevent premature failure.

Conclusion

In summary, check valves are indispensable components in modern plumbing systems. Their ability to prevent backflow protects water quality, ensures the efficient operation of pumps and other equipment, and safeguards homes and public water systems from contamination and damage. Whether in residential, commercial, or industrial applications, choosing the right valve for the job and performing proper maintenance can make the difference in system performance and longevity.

By understanding how these types of valves work, the types available, and their importance in preventing backflow, both plumbers and homeowners can make informed decisions when designing or maintaining plumbing systems. If you liked what you learned in this article, we invite you to read our article on sewage where you will find equally important information.

0 Comments