Booster pumps are essential equipment in residential and commercial plumbing systems, designed to solve low water pressure problems. Their main function is to increase the flow and pressure of the liquid, ensuring efficient delivery to faucets, showers, appliances, and industrial processes. These pumps act as intermediaries between the water source (such as the municipal supply or a storage tank) and the end-use points, especially in situations where natural pressure is insufficient.

How do booster pumps work?

The operating principle of booster pumps is based on centrifugal energy. These pumps use a motor-driven impeller, which spins at high speed to accelerate the water. This motion converts kinetic energy into pressure, similar to how fan blades generate airflow. Water enters through an inlet connection, is accelerated by the impeller, and exits through the discharge with increased pressure.

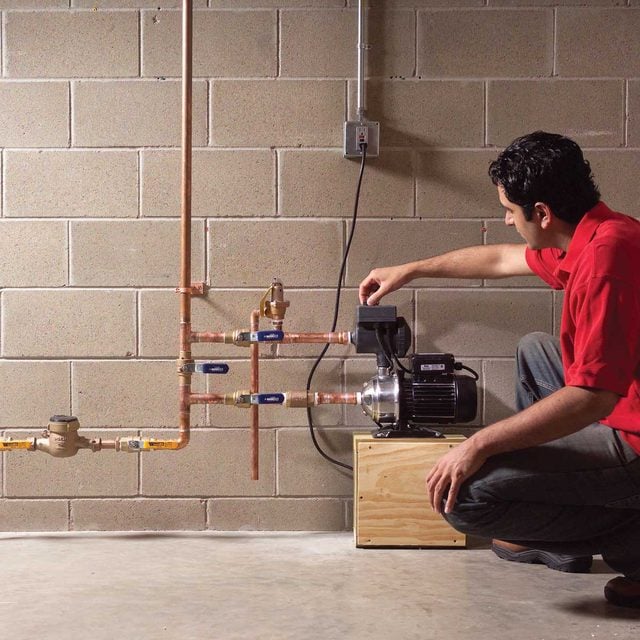

In plumbing applications, booster pumps are typically installed near the point where water enters the property. This strategic location allows pressure to be maximized before the liquid is distributed through the pipes. For complex cases, such as systems requiring ultra-high pressure or serving multiple buildings, multi-stage pumps are used, which increase pressure in gradual sequences.

Causes of Low Water Pressure

- Gravity in Multi-Story Buildings: Water struggles to reach higher floors due to gravitational resistance, reducing pressure in upper levels.

- Pipe Friction from Distance or Narrow Diameters: Long pipelines or small pipe diameters create friction, restricting water flow and lowering pressure.

- Water Treatment Systems: Filters, reverse osmosis units, or other treatment devices increase resistance, reducing pressure downstream.

- Municipal Supply Limitations: Inherently low pressure from public water systems, especially in high-demand areas or with aging infrastructure.

- Plumbing Issues: Clogged pipes, corroded valves, or faulty fixtures obstruct water flow, worsening pressure problems.

Note: Booster pumps are often recommended to counteract pressure loss caused by gravity, treatment systems, or municipal supply limitations.

Applications of booster pumps in residential and commercial plumbing

Booster pumps are versatile and adapt to a variety of needs. In homes, they improve the daily experience by ensuring showers with good flow, faucets that fill quickly, and appliances such as washing machines that function optimally. In apartment complexes or hotels, they are essential for supplying upper floors where natural pressure would be insufficient.

In commercial settings, these pumps are key for HVAC systems that depend on constant water flow, water treatment plants, and industrial processes that require stable pressure. For example, in reverse osmosis systems, booster pumps compensate for the pressure loss caused by filter membranes, ensuring efficient performance.

How to choose the right booster pump?

Selecting the right booster pump involves analyzing three main variables: flow rate, pressure, and application type. Flow rate is measured in gallons per minute (GPM) and should be calculated by adding the simultaneous demand of all fixtures (showers, faucets, etc.). For example, a home with two bathrooms and a kitchen might require a minimum of 8-10 GPM.

Pressure, measured in pounds per square inch (PSI), should be adjusted to avoid pipe damage. Most homes operate between 40 and 60 PSI. Exceeding this range can cause leaks or premature wear. It is also crucial to consider whether the pump will operate with cold or hot water, as some materials cannot withstand high temperatures.

For simple installations, single-stage pumps are sufficient. However, in projects requiring high pressure or continuous service, such as office buildings, multi-stage pumps or variable-speed models offer greater efficiency.

Installation and Maintenance

Booster pumps should be installed following professional practices to ensure safety and efficiency. Ideally, they are placed near the main water inlet, accompanied by a bypass system that allows flow to bypass the pump during maintenance. Flexible connectors help reduce vibration and noise, while pressure gauges allow real-time pressure monitoring.

Maintenance includes annual inspections of seals and gaskets to prevent leaks, cleaning inlet filters, and verifying motor performance. In areas with hard water, installing a softener is recommended to prevent sediment buildup in the impeller.

Conclusion

Booster pumps are indispensable technical solutions in modern plumbing systems. By understanding their operating principles, applications, and selection criteria, users and professionals can optimize water supply, ensuring comfort in homes and efficiency in commercial settings. Their implementation not only solves immediate pressure problems but also extends the life of pipes and appliances.

0 Comments